Microwave Synthesis Method Produces MXene Faster, Using Less Energy

Media Inquiries

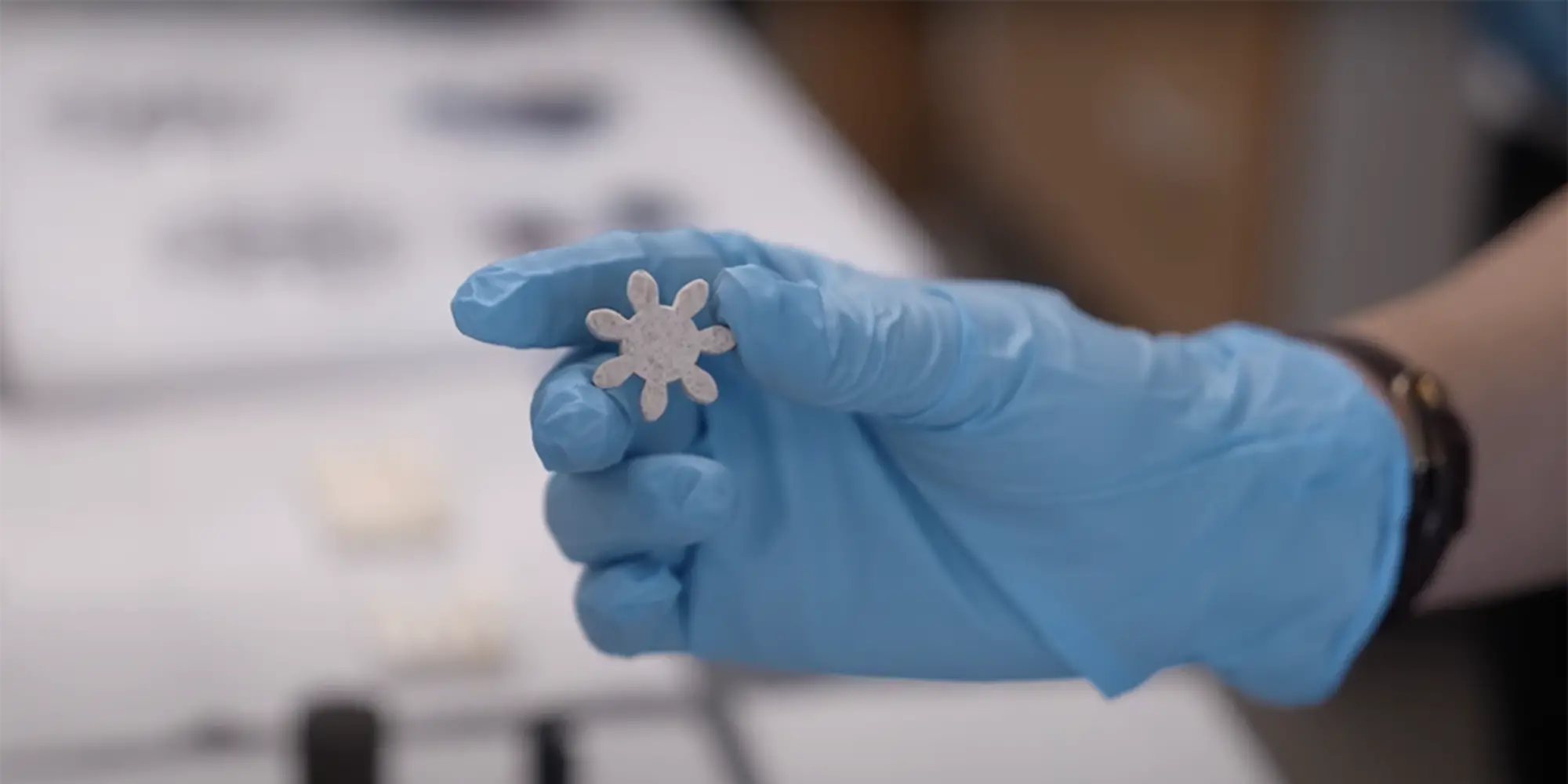

MXenes are a lightweight two-dimensional material capable of protecting spacecrafts, mechanical components — and maybe even people — from harmful radiation. Because traditional synthesis requires multistep processes that can take up to 40 hours, MXene is difficult to produce.

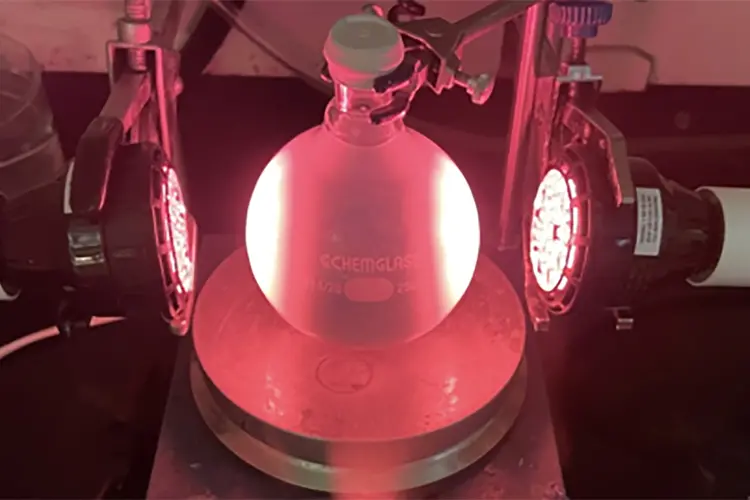

By introducing a rapid single-step microwave synthesis method, Carnegie Mellon University's Reeja Jayan(opens in new window) has reduced MXene production time to 90 minutes and cut energy consumption by 75%.

“Our work has implications for the global production of chemicals because almost a third of green-house gas emissions come from chemical manufacturing and production,” said Jayan, a professor of mechanical engineering at Carnegie Mellon.

The research, published in Materials Science in Semiconductor Processing(opens in new window), also demonstrates a unique ability to customize MXene’s composition to change the type of radiation that the material can protect against. To date, the team has tested their material across the X-band–radio frequencies ranging from 8.0-12.0 GHZ, but to protect against electronic materials in outer space, more testing against cosmic radiation is needed.

“We assumed that, because we sped up the process, we would lose some of the shielding performance in return,” said Jayan. “We were pleasantly surprised that, although there are subtle structural differences, we didn’t see any shielding efficiency tradeoff at the lab scale.”

Moving forward, Jayan will test her synthesis process at a larger scale. In partnership with an aerospace materials manufacturer, her team will integrate MXene into test panels for radiation testing.

“We’ve developed a low-carbon process that significantly saves energy. If it can be scaled up now, more than ever before, we stand to create a critically needed and substantial environmental impact.”