Pickleball Paddles of the Future

Materials science and engineering students investigated whether pickleball paddles produced by 3D printing could be as good as, or better, than those produced using existing techniques.

Media Inquiries

Pickleball courts are popping up all over the country, from parks to indoor facilities. For the last four years, the sport has been the fastest growing sport in America, drawing more than 48 million players in 2023. As the sport has expanded, so too has the design of its equipment.

The USA Pickleball Equipment Evaluation Committee (EEC) and its third-party accredited independent lab tested and approved 1,713 new paddle and ball submissions in 2024. Of these, 1,225 paddles and 81 balls were approved, and a total of 476 new manufacturers and brands were registered.

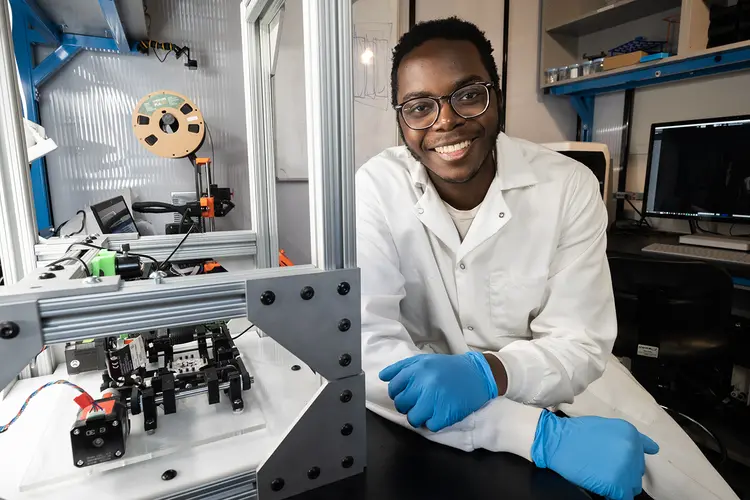

A group of Carnegie Mellon University materials science and engineering (MSE)(opens in new window) undergraduate students has gotten into the game this year, working with Paddle Tap Pickleball(opens in new window) on their capstone project, “3D Printing the Pickleball Paddles of the Future.” The group aimed to investigate whether pickleball paddles produced by 3D printing could be as good as, or better, than those produced using existing techniques, such as thermoforming.

The capstone course(opens in new window) serves to provide senior level students with an opportunity to work together in small groups to apply the knowledge they have accumulated over the course of their time in the MSE program to a real-world problem as identified by industry partners.

Mable Dong was drawn to this project not only because of her personal interest in pickleball, but also because of the opportunity to observe the project’s full cycle.

“Coming from a product management background, I highly value being able to follow a project from ideation to launch or, in this case, from ideation to validation,” Dong said.

As the project was started in the fall semester, the team had to determine how to navigate various challenges. The constraints of 3D printing affected their design approach, as they initially wanted to create a complex 3D metamaterial structure but quickly realized that the fine overhangs they had envisioned were impossible to print using a Fused Deposition Modeling (FDM) printer.

“Instead of seeing this as a limitation, we took it as an opportunity to explore creative alternative designs,” noted Jessica Shi. “We turned to nature for inspiration, studying bio-inspired structures like honeycombs and bamboo cross-sections — structures that are naturally stable, lightweight and tolerant to defects.”

As part of their project, group members tested mechanical properties of the paddles, such as fatigue, impact toughness and elasticity, and also examined the microstructure of the 3D- printed materials. In order to test their design, the team had to gain an understanding of the industry standards and adapt to the capabilities available to them.

“Some of the required testing equipment is custom-made, making it difficult to replicate due to limited equipment and the lack of pre-programmed testing capabilities,” said Phylicia Ma. “We did our best to replicate the testing processes, sometimes comparing our results to those of Paddle Tap Pickleball’s paddle to assess whether our paddles met industry standards."

Throughout the year, the group has worked to enhance their design in order to produce a final product to present to their sponsor at the culmination of the project cycle.

“We applied concepts from our Structures of Materials core course, particularly principles of crystal structures and atomic packing, to refine our infill designs,” said Shi. This approach solved our manufacturing challenges and deepened our appreciation for how efficiently nature engineers materials.”

The group is hopeful that this proof-of-concept project influences pickleball paddle manufacturers to adopt 3D printing technology into their processes, fueling both sustainability and innovation for the next generation of paddles.

“Using this process, each paddle only requires the exact amount of material needed for printing, eliminating the issue of plastic waste that is common in other manufacturing methods,” said Allison Silva. Silva also noted that the use of Computer-Aided Design (CAD) has potential to create complex architectures that better increase power, deflection and spin.

All students in the capstone course had the opportunity to provide a mid-year update to faculty, sponsors and peers in the MSE department at the end of the fall semester, and this particular group also took advantage to showcase their work at the TechSpark Engineering Exposition, where they were recognized with Covestro's Most Innovative award for being creative and novel in approach or execution.

In addition to problem solving as a team, the students developed skills above and beyond materials science as they explored design constraints and developed proficiency with drafting and analysis software.

“Although we are still material scientists at our core, this project allowed us to take a more holistic approach, which has deepened our understanding of the design process,” said Julea Farchione. “Gaining experience in these aspects will enhance our ability to communicate effectively with engineers and future colleagues, whether in industry or academia.”

Paddle Tap Pickleball co-founder Alan Laymon advised the group throughout the project and believes that the end results have potential to lead to industry innovation.

“The pickleball industry is moving very quickly and working with the CMU students provided amazing feedback on how the structural design of a paddle can be improved,” said Laymon.